A Complete Guide to Meeting Your Chemical Logistics Needs with All Chemical

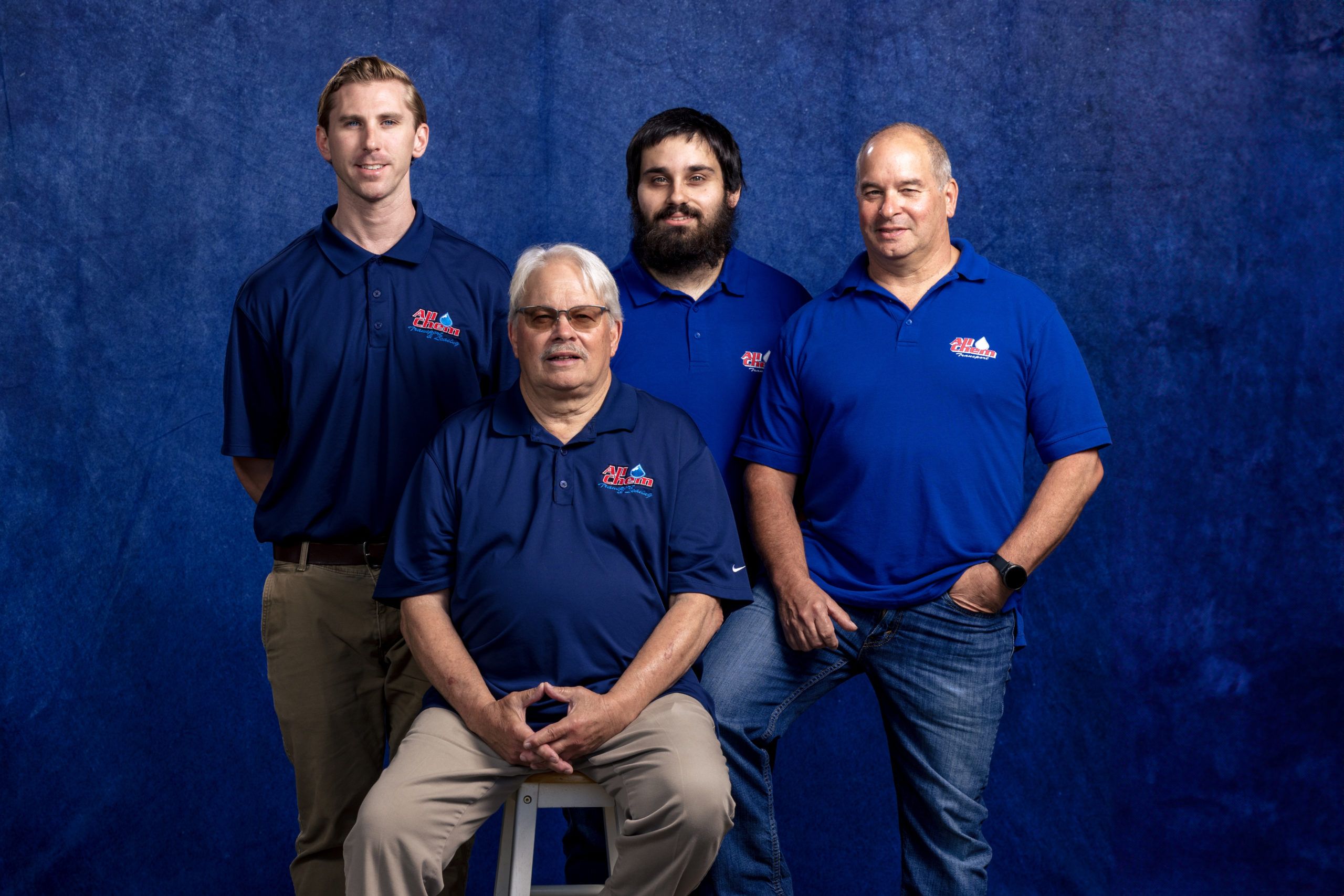

A Complete Guide to Meeting Your Chemical Logistics Needs with All Chemical We love to provide a behind-the-scenes glimpse into the workings of All Chemical. You’ve met a few of our stellar staff members, and regularly hear from members of our leadership team, like our Founder and Owner, Steve Quadrel.

Now, we’re peering behind the curtain to look deeper into the process our team conducts with existing customers expanding their services with us, or customers that are new to All Chemical.

Here are some of the most commonly asked questions our team receives. From our team to yours – here’s a helpful recap to continue to fulfill your service needs with us.

Q: How will we work together?

A: We’ve made it a best practice to dive into the “who, what, when, where, and why” of our customer’s needs to gather all of the necessary details we need to be your seamless, reliable, one-stop-shop partner for your bulk liquid transportation needs. We pride ourselves on being a one-stop-shop for all of our customers’ needs and going above and beyond to take on jobs others cannot, will not, and do not.

We will take the time to learn more about your company, your needs and pain points and provide a contract for our services. If you agree to it, we’ll collect the necessary billing information and get started with your chemical transportation needs.

Q: Why All Chemical?

A: We’re a family-owned business, serving our community since 1978. We are well-known industry leaders, early adopters of technology and innovative pioneers. We have a strong focus on excelling in safety, compliance, and customer service. We pride ourselves on being a one-stop-shop for all of our customers’ needs and going above and beyond to take on jobs others cannot, will not, and do not.

Q: Tell me about your safety and compliance standards.

A: Our standards are high and our efforts are rigorous! Our truck drivers and staff are well trained and expertly qualified. They are diligently vetted for government work and nuclear power plants, with a team of reserve staff waiting in the wings when emergency strikes. We have all of the necessary credentials: CDL-certified, HME, and TWIC!

In short, our resilient team holds the gold standard in effort, expertise, and care.

Q: The industry is turbulent. How do we know you’ll be there when we need you?

A: Our people are our priority. We assure stability through loyalty to our team, and to you. Our industry has tremendously high rates of truck driver turnover—in fact, the national average turnover rate for our industry is a whopping 80–90%.

Ours is 5%.

In addition to our unparalleled safety standards and top-of-the-line equipment, the secret is a mix of competitive pay, high-quality healthcare and retirement benefits. We aim to be here when and where you need us with our dedicated, customer-focused team.

Q: What additional services are you offering due to the recent construction?

A: We finished construction upgrades on our Lakewood, NJ HQ to greatly increase our capacity, enabling us to handle much larger volumes of product while maintaining our high safety standards. This includes 2 new wash bays, 16 additional steam stations, 4 new ISO container storage pads, and a state of the art wastewater treatment facility.

That means more tanks and trailers to wash and steam for you!

Here’s a reminder of our steam and wash options:

Tank Washing:

- Standard chemical washes

- Diesel washes

- Specialized washes for heavy, oil-based products

- USP/Food grade washes

- Kosher-certified washes (Standard)

- Kosher-certified Upgrade washes (or “Rekosherization”)

Tank Steaming:

- Low- and high-pressure capabilities

- Steam-regulating capabilities

- Hot water heating

- Capacity to put over 50 containers on steam simultaneously

- Redundancy with two independent steam boilers

- On-call boiler maintenance to fix an issue immediately: 24/7, 365 days a year

- 24/7 monitoring with fixed interval monitoring, as requested by the customer

- Biometric probing with real-time temperature updates and automated temperature monitoring

Q: Who are a few of your long-standing partners, and routinely carried chemicals?

A: While we take on unique and speciality jobs more often than not, we do have some tried and true long-standing customers and routinely carried chemicals. We are the trusted providers for power, water, and pharmaceutical companies and regularly carry glycerin, caustic, bleach, ethanol, acetone, methanol, and transformer oil.

If you don’t see your product on this list, and have unique storage and chemical needs, give us a call! We’re prepared down to the smallest detail, and we always follow through. It would be our pleasure to help.

Meet Jim

Meet Jim